.png)

.png)

All of the raw material, i.e., stainless steel coils, is acquired from our trusted partner Jindal Stainless Limited (JSL).

Grade

Current MOU

Breadth

JSL issued code

Thickness

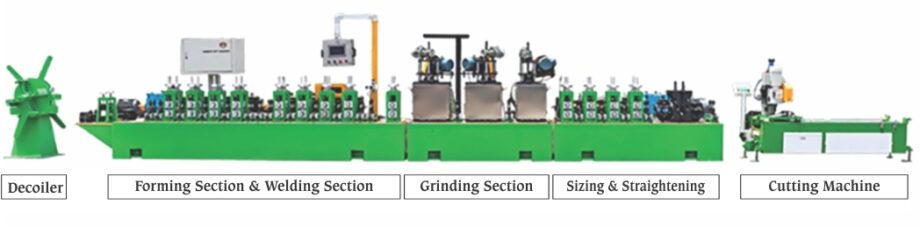

The complete manufacturing of pipes is done mechanically with high precision and efficiency with the help of the latest technology.

Starting with the initial production of 100 tons and only specializing being in mild steel, we have outgrown our competitors with fully functional specialization in stainless steel, complemented by focusing on prevalent size categories from 0.45 mm to 2 mm.

The stainless strips from the decoiler passes first through the stamping device to get the stamp of JDL along with JSL and its issued factory code.

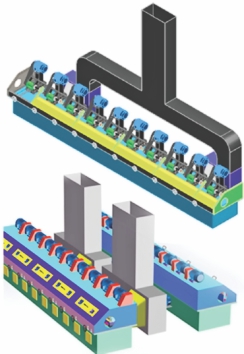

The strips then pass through the number of rollers as per the required size. In the tubes-mill, the strip is gradually converted into the tubular shape.

Following different stages of grinding, sizing and straightening, (under the constant flow of water and lubricants) the unpolished pipe comes out through the other end, After passing the fixed length of 20 feet, the fitted automatic cutter cuts the pipe and releases it into the nearby attached storing section. The finished pipes are then taken to the polishing machine to get the finished product.

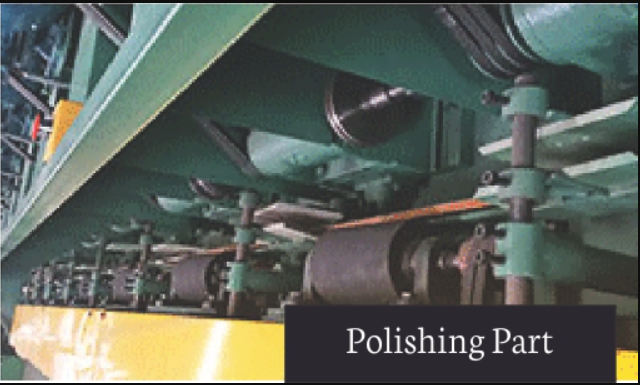

The polishing process with a speed of about 190 feet per minute. With every two polishing machines a dust collector is attached to make to complete process clean and healthy for the employees. The dust collector collects, with the use of high-powered fans, all the waste released during the polishing in an underground tunnel which has a continuous flow of recycling water to prevent any fire hazards, since the waste is usually highly inflammable.

The unpolished pipes pass through the polishing machine (round pipes in round polishing machine and square/ rectangular pipes in square/rectangular machine). Where with the use of special polishing material and rotating cleaning mechanisms systematically polishes the pipes with all the dust and waste collected underground using the dust collector.

The foreman controls and manages the complete process using one special panel for all the functions called the intelligent console. The polished pipes are then bundled together, properly packed and loaded to buyer’s trucks.